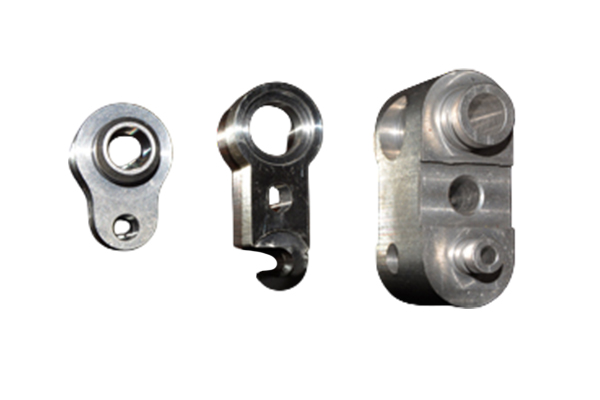

Aluminum connectors play a crucial role in automotive air conditioning (AC) systems, ensuring efficient coolant flow between components. These connectors are widely used due to their lightweight, corrosion resistance, and high thermal conductivity.

Key Features

- Material: Typically made from high-grade aluminum alloys (e.g., 6061, 6063, 7075) to withstand pressure and temperature variations.

- Precision Machining: Manufactured using CNC machining to achieve tight tolerances for leak-proof connections.

- Surface Treatment: Anodized, coated, or passivated for enhanced durability and resistance to corrosion.

- Weight Reduction: Aluminum is much lighter than steel, improving fuel efficiency and vehicle performance.

- Compatibility: Designed to fit with hoses, pipes, compressors, evaporators, and condensers in the AC system.